Consumers and chefs prefer посуда из нержавеющей стали because it is durable against corrosion, efficient in transferring heat, and stable at high temperatures, ensuring food health and safety in the modern kitchen.

The entire manufacturing process of stainless steel cookware starts with the choice of material, goes through stamping and molding, surface treatment, welding and assembly, and ultimately quality inspection and final packaging. Each step of this process is precisely engineered and strictly controlled to ensure that each cooking implement meets high-quality standard criteria.

Оглавление

ToggleMaterial Selection and Preparation

The first step in the stainless steel cookware manufacturing process is selecting high-strength, corrosion-resistant stainless steel, such as 304 stainless steel. Raw materials in this source are highly reputed suppliers assuring purity and performance. Any impurities present, or defects in the material, would result in shortcomings in the durability of the cookware and possible lifespan.

Material Testing

Comprehensive tests are conducted to meet strict quality standards.

Cutting and Shaping

For regular shapes, high-speed punch presses are used to cut stainless steel into specific sizes and shapes. For irregular or highly precise designs, advanced laser or plasma cutting technology is employed.

Stamping and Forming

After preparation, the stainless steel is shaped into its basic cookware form.

Stamping

High-pressure machines (150 tons or more) press the stainless steel into its initial shape. Precision control is crucial to ensure accuracy.

Forming

Hydraulic presses are used to refine the cookware’s shape, removing excess material and ensuring smooth edges.

Deep Drawing

For tall or complex pots, deep drawing techniques stretch the material multiple times under controlled conditions, with heating to 800°C to prevent stress cracks.

Surface Treatment

The surface treatment stage is essential to enhance both the appearance and durability of stainless steel cookware.

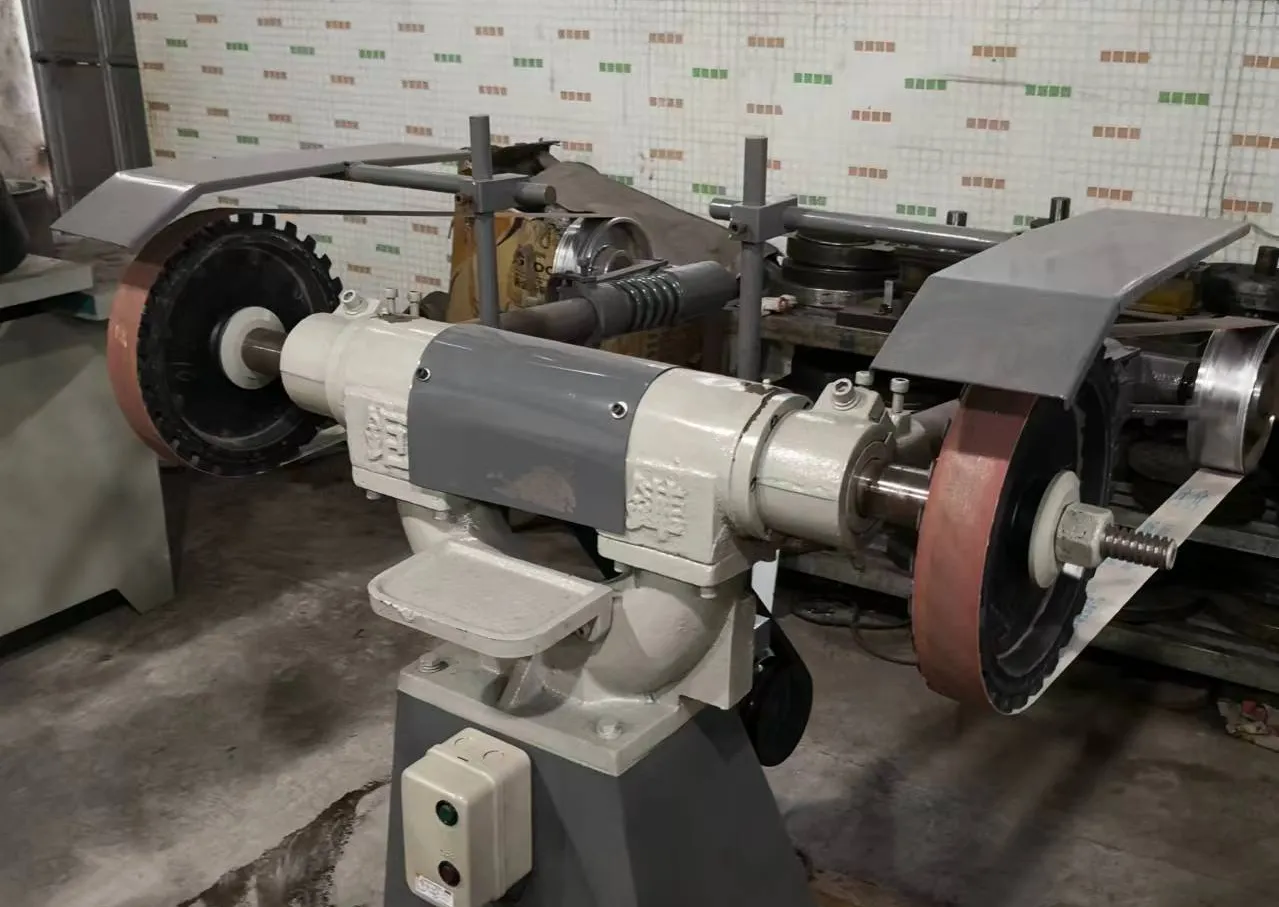

Grinding

The surface of the cookware is ground to remove scratches and burrs.

Polishing

Further, with the help of better advancements in machines or polishing liquids, there is an enhancement in giving cookware a mirror-like finish, as well as making it prettier to look at and less apt to corrode

Optional Treatments

There are additional processes such as sandblasting or electroplating as another argument for protective and aesthetic treatment.

Welding and Assembly

In this stage, all parts of the cookware, including handles and lids, are assembled.

Welding

High-temperature welding ensures a durable bond between handles and cookware bodies. For some designs, riveting is used instead.

Assembly

The cookware is carefully assembled, ensuring tight and precise fittings of all components.

Quality Inspection and Packaging

Quality control is a critical step in the stainless steel cookware manufacturing process.

Inspection

Each piece undergoes visual checks for surface defects and machine checks for thickness, weight, and durability. Salt spray and endurance tests ensure the cookware meets rigorous standards.

Упаковка

Approved products are carefully packaged to prevent damage during storage and transport, ensuring they reach customers in perfect condition.

About Chancescook

Chancescook, a leading stainless steel cookware manufacturer, specializes in providing OEM and ODM services with a focus on one-stop customization solutions. The company leverages its expertise in the процесс производства посуды из нержавеющей стали to deliver superior products tailored to meet clients’ unique requirements. With state-of-the-art facilities and a dedicated team, Chancescook ensures every piece of cookware combines functionality, durability, and modern design.