يفضل المستهلكون والطهاة أواني طهي من الفولاذ المقاوم للصدأ لأنها متينة ضد التآكل، وفعالة في نقل الحرارة، وثابتة في درجات الحرارة العالية، مما يضمن صحة الطعام وسلامته في المطبخ الحديث.

كامل عملية تصنيع أواني الطهي المصنوعة من الفولاذ المقاوم للصدأ يبدأ ب اختيار المواد، مرورًا بالختم والقولبة، والمعالجة السطحية، واللحام والتجميع، وأخيرًا فحص الجودة والتعبئة النهائية. كل خطوة من هذه العملية مصممة بدقة ومراقبة صارمة لضمان أن كل أداة طهي تلبي المعايير القياسية عالية الجودة.

جدول المحتويات

تبديلاختيار المواد وإعدادها

تتمثل الخطوة الأولى في عملية تصنيع أواني الطهي المصنوعة من الفولاذ المقاوم للصدأ في اختيار الفولاذ المقاوم للصدأ عالي القوة والمقاوم للتآكل، مثل الفولاذ المقاوم للصدأ 304. المواد الخام في هذا المصدر من موردين مشهورين للغاية لضمان النقاء والأداء. فأي شوائب موجودة أو عيوب في المادة ستؤدي إلى قصور في متانة أواني الطهي والعمر الافتراضي المحتمل.

اختبار المواد

يتم إجراء اختبارات شاملة لتلبية معايير الجودة الصارمة.

التقطيع والتشكيل

بالنسبة للأشكال المنتظمة، تُستخدم مكابس التثقيب عالية السرعة لتقطيع الفولاذ المقاوم للصدأ إلى أحجام وأشكال محددة. وبالنسبة للتصميمات غير المنتظمة أو الدقيقة للغاية، يتم استخدام تقنية القطع بالليزر أو البلازما المتقدمة.

الختم والتشكيل

بعد التحضير، يتم تشكيل الفولاذ المقاوم للصدأ في شكل أواني الطهي الأساسية.

الختم

تقوم ماكينات الضغط العالي (150 طن أو أكثر) بضغط الفولاذ المقاوم للصدأ في شكله الأولي. التحكم الدقيق أمر بالغ الأهمية لضمان الدقة.

التشكيل

تُستخدم المكابس الهيدروليكية لصقل شكل أواني الطهي وإزالة المواد الزائدة وضمان نعومة الحواف.

الرسم العميق

بالنسبة للأواني الطويلة أو المعقدة، يتم استخدام تقنيات السحب العميق لتمديد المادة عدة مرات في ظروف خاضعة للرقابة، مع تسخينها إلى 800 درجة مئوية لمنع حدوث تشققات إجهادية.

معالجة السطح

تُعد مرحلة معالجة السطح ضرورية لتحسين مظهر أواني الطهي المصنوعة من الفولاذ المقاوم للصدأ ومتانتها.

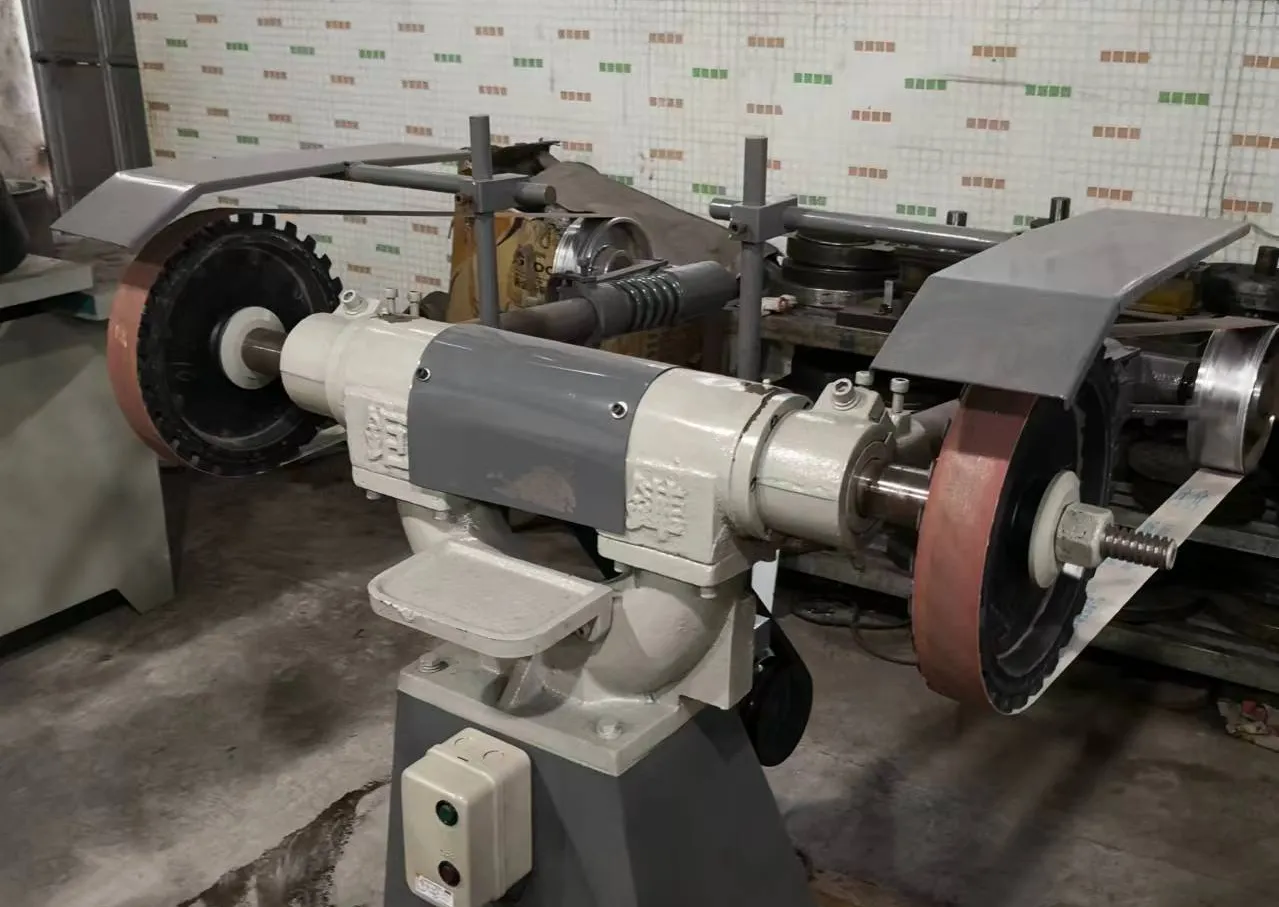

الطحن

سطح أواني الطهي مطحون لإزالة الخدوش والنتوءات.

التلميع

وعلاوة على ذلك، بمساعدة التطورات الأفضل في الآلات أو سوائل التلميع، هناك تحسن في إعطاء أواني الطهي مظهرًا يشبه المرآة، بالإضافة إلى جعلها أجمل في المظهر وأقل عرضة للتآكل

العلاجات الاختيارية

هناك عمليات إضافية مثل السفع الرملي أو الطلاء الكهربائي كحجة أخرى للمعالجة الوقائية والجمالية.

اللحام والتجميع

في هذه المرحلة، يتم تجميع جميع أجزاء أواني الطهي بما في ذلك المقابض والأغطية.

اللحام

يضمن اللحام بدرجة حرارة عالية وجود رابطة متينة بين المقابض وأجسام أواني الطبخ. بالنسبة لبعض التصميمات، يتم استخدام التثبيت بدلاً من ذلك.

التجميع

يتم تجميع أواني الطهي بعناية، مما يضمن تركيبات محكمة ودقيقة لجميع المكونات.

فحص الجودة والتعبئة والتغليف

تعتبر مراقبة الجودة خطوة حاسمة في عملية تصنيع أواني الطهي المصنوعة من الفولاذ المقاوم للصدأ.

الفحص

تخضع كل قطعة لفحوصات بصرية للتأكد من عدم وجود عيوب في السطح وفحوصات آلية للسمك والوزن والمتانة. تضمن اختبارات رش الملح واختبارات التحمل أن أواني الطهي تفي بالمعايير الصارمة.

التعبئة والتغليف

يتم تغليف المنتجات المعتمدة بعناية لمنع تلفها أثناء التخزين والنقل، مما يضمن وصولها إلى العملاء في حالة ممتازة.

نبذة عن تشانسيسكوك

تشانسيسكوك, شركة رائدة في تصنيع أواني الطهي المصنوعة من الفولاذ المقاوم للصدأمتخصص في توفير خدمات تصنيع المعدات الأصلية وتصنيع المعدات الأصلية مع التركيز على حلول التخصيص الشاملة. تستفيد الشركة من خبرتها في عملية تصنيع أواني الطهي المصنوعة من الفولاذ المقاوم للصدأ لتقديم منتجات فائقة الجودة مصممة خصيصًا لتلبية متطلبات العملاء الفريدة. بفضل مرافقها المتطورة وفريقها المتخصص، تضمن تشانسيسكوك أن كل قطعة من أواني الطهي تجمع بين الأداء الوظيفي، والمتانة، والتصميم العصري.